Alubond FR-A2

Alubond U.S.A is an Aluminum composite Panels (ACP) and Metal Composite Material (MCM) Panels brand owned by Mulk Holdings. The company has emerged as the World’s largest ACP and MCM brand with a twenty five million square meters of manufacturing and processing capacity from its various facilities in Europe, UAE, Turkey, Ghana and India. Alubond has also expanded its products to offer a full range of Fire Rated Metal Panels including A2 Mineral Core ACP, B Mineral Core ACP, Solid Aluminum, Honeycomb, Exotic metals MCM in a choice of metal skins like Galvanized Steel, Stainless Steel, Copper, Bronze and Titanium.

The company in addition to production of metal composites also has a complete backward and forward integration manufacturing facilities producing Fire rated Mineral Core, Fire Rated adhesive films and Color Coated coils.

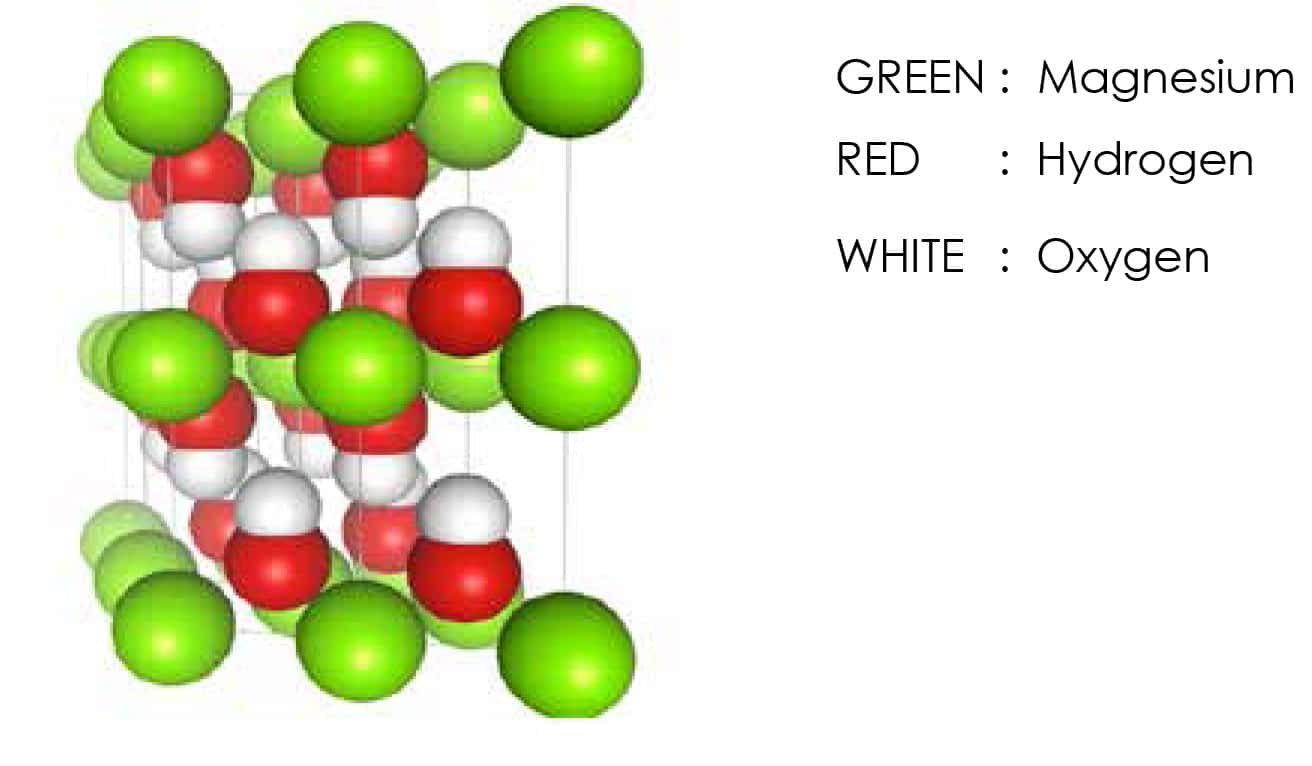

SOLID MAGNESIUM HYDROXIDE IN A ROCK FORM

The solid mineral magnesium hydroxide, with the chemical formula Mg(OH)2 is a common alteration product of periclase in marble; a low-temperature hydrothermal vein mineral in metamorphosed limestones and chlorite schists; and formed during serpentinization of dunites. It is often found in association with serpentine, calcite, aragonite, dolomite, magnesite, hydromagnesite, artinite, talc and chrysotile.

Advantages of Magnesium Hydroxide

- Filler and Flame Retardant/Smoke Suppressant in one product

- Environmentally Acceptable

- Halogen Free

- Non-Corrosive

- Reduces Smoke Density

- Non-Volatile

- Largely Inert

- Thermally Stable up to 340º C and thereafter undergoes Endothermic Decomposition releasing Water

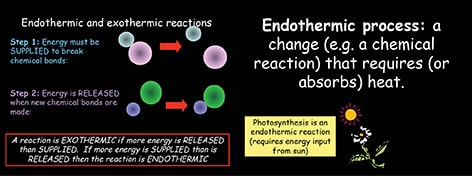

What is Endothermic & Exothermic Reaction?

LDPE (Low density Polyethylene) is a hydrocarbon material which exhibits exothermic reaction by releasing energy when exposed to heat. Mg (OH)2 is a natural mineral which exhibits Endothermic reaction by absorbing heat when exposed to energy/ heat.

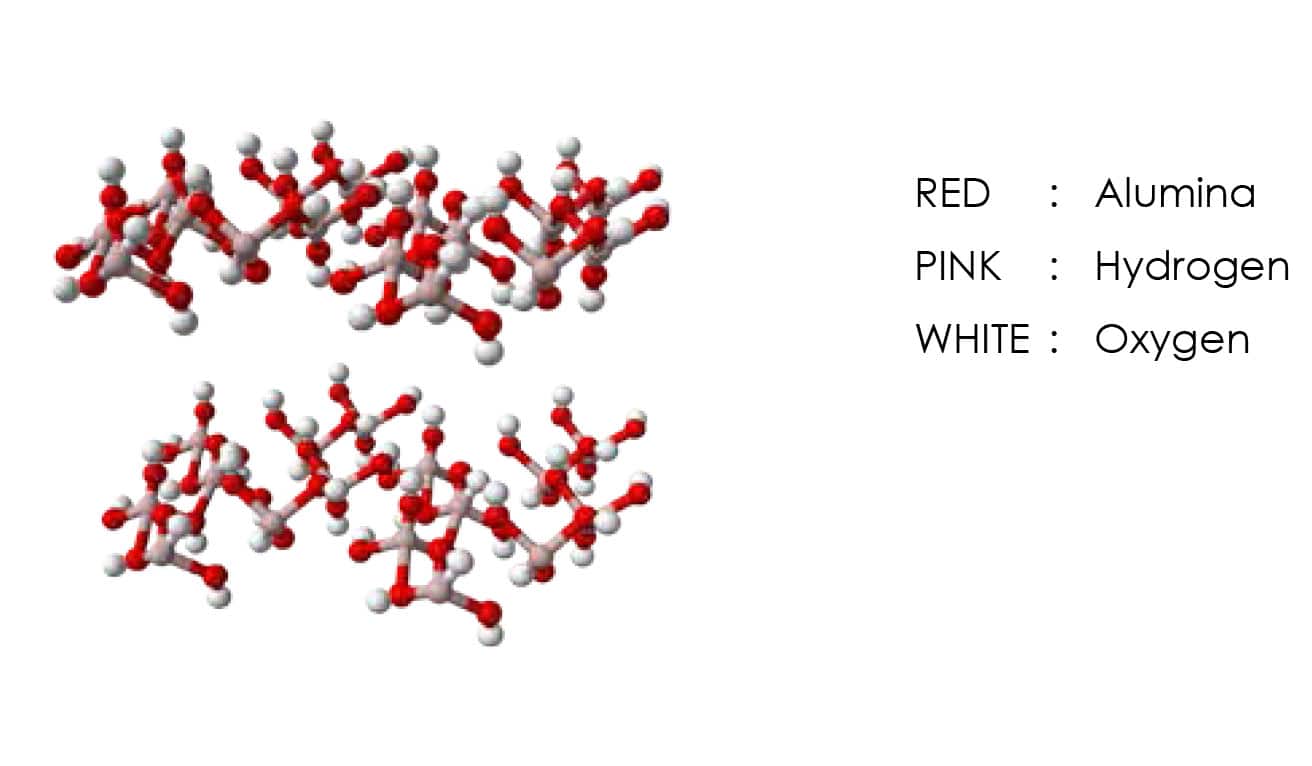

Magnesium Hydroxide Structure :

Aluminum Trihydrate Structure

Comparison of Magnesium hydroxide with Aluminum trihydrate

ATH | Magnesium Hydroxide | |

Molecular Formula | Al (OH)3 | Mg (OH)2 |

Water Content Loss on Ignition (LOI) | 34% | 31% |

Decomposition Temperature) | Greater than 230º C | Greater than 330º C |

Mohs hardness | 2.5–3.5 | 2.0-3.0 |

Specific Gravity | 2.42 | 2.36 |

pH | 10-8 | 10.5 |

Electrical Conductivity us/cm | Less than 350DIN | 53208 |

Color | White | White |

Physical Properties | Powder | Powder |

Refractive Index | 1.57 | 1.58 |

Particle Morphology | Hexagonal Platelet | Hexagonal Platelet |

Dimension Tolerance

Panel Thickness | : | 4 mm |

Alloy Series | : | 1xxx, 3xxx, 5xxx |

Width | : | 1000 mm, 1250mm, 1500 mm |

Length | : | upto 6000 mm |

*special sizes on request, min quantity 2000sqm (incl 1000mm width)

Mechanical Properties

Thickness | ± 0.05 | 0.5 mm |

Weight | ± 0.05 | 8 Kg/m2 |

Standard Width | ± 2 | 1250 mm |

Panel thickness | ± 0.03 | 4 mm |

Thermal Properties

Alloy 1xxx, | Alloy 3xxx | Alloy 5xxx | |||

Section Modulus(W) | DIN 53293 | cm³/m | 1.62 | 1.7 | 1.75 |

Rigidity (Poisson›s ratio μ = 0,3) | DIN 53294 | KN cm2 /m | 2300 | 2320 | 2400 |

Alloy | EN 573-3 | …….. | EN AW- 1100 | EN AW- 3105 | EN AW- 5005A |

Temper | EN 515 | …….. | H16/H18 | H14/H16 | H16/18 |

Modulus of Elasticity | EN 1999 1-1 | N/mm2 | ≥70000 | ≥70000 | ≥70000 |

Tensile Strength of Aluminium | EN 485-2 | N/mm2 | Rm ≥ 135 | Rm ≥ 140 | Rm ≥ 145 |

0.2% Proof Stress | EN 485-2 | N/mm2 | Rpo ≥ 85 | Rpo ≥ 90 | Rpo ≥ 95 |

Elongation | EN 485-2 | % | A50 ≥ 6 | A50 ≥ 5 | A50 ≥ 5 |

Linear Thermal Expansion | EN 1999 1-1 | mm/m @100°C | 2.4 | 2.4 | 2.4 |

Thermal resistance R | ASTM C518 | M2 K/W | 0.007 | 0.009 | |

Temperature resistance | ASTM C518 | °C | -50….+80 |

Dimension Tolerance

Thickness | + /- 0.05 | 0.5 mm |

Weight | + /- 0.05 | 8 Kg/m2 |

Width | ± 2 | 1250 mm |

Panel thickness | ± 0.03 | 4 mm |

Core Properties

Core | EN 13501-1:2007+ | CLASS- A2,S1,d0 Passed | Mg (OH)2 |

Surface Burning test | ASTM E84 | …… | Passed |

Fire Behaviour | AS 1530 PART 3 | …… | Passed |

Fire Behaviour | BS 476 | Part 6 Class 0 & Part 7 Class 1 | Passed |

Panel Thickness | : | 4 mm |

Skin Thickness | : | 0.5 mm |

Weight | : | 7 Kg / M 2 |

| Alloy Series | : | 1xxx, 3xxx, 5xxx |

Width | : | 1250mm, 1500 mm |

| Length | : | upto 6000 mm |

*special sizes on request, min quantity 2000sqm (incl 1000mm width)

Fire Behaviour Properties

Fire Behaviour | FR Classification | Section Number | Document Number | Testing Agency |

BS 476 part 6&7 | part 6 class 0 part 7 class 1 | 6&7 | Certificate No : CF 5061 | EXOVA WARRINGTON-UK |

EN 13501–1 | B, s1, d0 | 1 | Certificate No : ME 5059 | EXOVA WARRINGTON-UK |

ASTM E 119 | Min 1 hr 42 Min fire rating | – | Report No : 01.12694.307 | SOUTH WEST RESEARCH INSTITUTE |

DIN 4102-1 | Class B1 | Part 1 | Report No : 2013-1400-2 | EXOVA WARRINGTON-UK |

NFPA 285 | Assembly Meet The requirements / Passed | As per UAE civil defense code 4.2.6 | Certificate No : WHI15 – 26553701 | Intertek usa & Thomas Bell Wright International Consultant |

ASTM | Class A : Passed | As per UAE civil defense code 4.2.4 &4.2.5 | Certificate No : WHI15 – 26553702 | Intertek usa & Thomas Bell Wright International Consultant |

Mechanical Properties

Section Modulus(W) | DIN 53293 | cm³/m | 1.62 | 1.7 | 1.75 |

Rigidity (Poisson›s ratio μ = 0,3) | DIN 53294 | KN cm2 /m | 2300 | 2320 | 2400 |

Alloy | EN 573-3 | …….. | EN AW- 1100 | EN AW- 3105 | EN AW- 5005A |

Temper | EN 515 | …….. | H16/H18 | H14/H16 | H16/18 |

Modulus of Elasticity | EN 1999 1-1 | N/mm2 | ≥70000 | ≥70000 | ≥70000 |

Tensile Strength of Aluminium | EN 485-2 | N/mm2 | Rm ≥ 135 | Rm ≥ 140 | Rm ≥ 145 |

0.2% Proof Stress | EN 485-2 | N/mm2 | Rpo ≥ 85 | Rpo ≥ 90 | Rpo ≥ 95 |

Elongation | EN 485-2 | % | A50 ≥ 6 | A50 ≥ 5 | A50 ≥ 5 |

Linear Thermal Expansion | EN 1999 1-1 | mm/m @100°C | 2.4 | 2.4 | 2.4 |

Thermal Properties

Thermal resistance R | ASTM C518 | M2 K/W | 0.03 | |

Temperature resistance | ASTM C518 | °C | -50….+80 | |

Thermal Transition | DIN 4108 | W/M²k | 5.34 | |

Core | CLASS B | Mg (OH)2 Based polymeric bonded core | ||

Type / Finish | —- | —- | PVDF | FEVE |

Gloss @600C | ECCA T2 | % | PVDF 20-45 | FEVE 20-80 |

Pencil hardness | ECCA T4 | …… | min HB | |

Sound absorbtion factor | ISO 354 | ……. | 0.05 | |

Sound transmission Loss (Rw) | ASTM E90 | dB | STC: 26 | OITC:22 |

Thickness | + /- 0.05 | 0.5 mm | ||

Weight | + /- 0.05 | 8 Kg/m2 | ||

Width | ± 2 | 1250 mm | ||

Panel thickness | ± 0.03 | 4 mm |

Core Properties

Core | EN 13501-1:2007+ A1:2009 CLAUSE 8 & NFPA 285 /BS6853 UBC17- | CLASS- A2,S1,d0 Passed | Mg (OH)2 |

Surface Burning test | ASTM E84 | …… | passed |

Fire Behaviour | AS 1530 PART 3 | …. | passed |

Fire Behaviour | BS 476 | Part 6 Class 0 & Part 7 Class 1 | Passed |

Surface Finish Properties

Accoustical Properties

Dimension Tolerance

Alubond-Stone (FR A2) – Endothermic Reaction

Alubond–Stone ‘s choice of Magnesium Hydroxide as its prime core mineral is based on the following data.

Reactivity :

Magnesium Hydroxide is much more reactive than Alumina Trihydrate (ATH), whereas ATH releases the available water over a broad range (230º C to 430º C), Magnesium Hydroxide releases the available water over a much narrower range (330º C or 630º F to 430º C). In simple terms this compares to spraying a fine mist of water over a fire (ATH) as opposed to dousing the fire with a full bucket of water (Magnesium Hydroxide). The quick release of water enhances the flame retardant properties of Magnesium Hydroxide.

Water Release :

Magnesium Hydroxide releases water at a higher temperature than ATH. The higher temperature release is at a more critical point that reduces the spread of the flame.

Particle Shape :

Magnesium Hydroxide particles, if viewed under a microscope, are plate-like versus the spherical particles of ATH. These plate-like particles overlap one another similar to fish scales or roofing shingles. Pound for pound these plate-like particles offer much more exposed surface area than spherical ATH particles. Therefore more particles are directly exposed to the flame. Also, the plate-like particles provide more strength, flexibility and reinforcement in the finished product as opposed to spherical particles.

Particle Integration :

Magnesium Hydroxide is a natural mix of particles. There is particle penetration and integration within Magnesium Hydroxide rather than having ATH and calcium carbonate particles mixed side by side. This allows a better distribution of the fire retardant and smoke suppressant properties.

Stability :

Magnesium Hydroxide has stabilizing characteristics that tend to neutralize acid and toxic smoke. ATH does not provide these benefits.

Char Ash :

Magnesium Hydroxide during the burning reaction forms a “Char-Ash” in front of the flame, which suppresses the flame.

Physical Properties

- Physical properties such as viscosity cure rate, stress strain and durometer, suggest that magnesium hydroxide is virtually indistinguishable from ATH from a filler performance standpoint.

- Magnesium Hydroxide, because of its acid scavenging properties, can play a useful role in halogenated compounds by reducing acid gas emissions.

- By absorbing the heat, magnesium hydroxide prevents or delays ignition and retards combustion of polymeric materials.

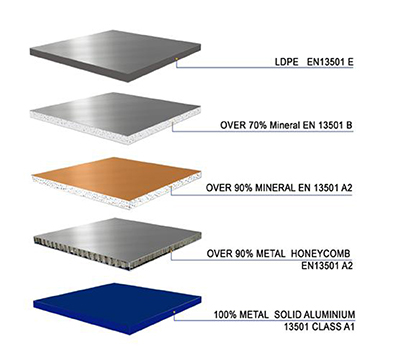

Different Types of Cores

PERFORMANCE | LDPE | OVER 70% Mineral EN 13501 B | OVER 90% MINERAL EN 13501 A2 | OVER 90% METAL | 100% METAL |

Combustibility Rating | Combustible | Low Combustibility | Non | Non-Combustible | Non-Combustible |

NFPA 285/ BS 8414 Pass | No | Yes | Yes | Yes | Yes |

ASTM E 84 Core | No | Yes | Yes | Yes | Yes |

ASTM D 1929 Ignition | No | Yes | Yes | Yes | Yes |

EN 13501 S1 D0 Rating | E | B | A2 | A2 | A1 |

Direct Flame Over | 20 Seconds | 18 Minutes | 30+ Minutes | 55 Seconds | 30 Seconds |

ALUMINIUM PANEL FIRE TEST:

A panel burning test was conducted with the direct flame at a temperature of 1500 0C on five different panels. The time the panels withstood fire was recorded as follows.

Panels | Time withstood by Panel |

LDPE Core – ACP | 20 Seconds |

Solid Aluminium | 30 Seconds |

B1 Core -ACP | 18 Minutes |

A2 Core -ACP | 30 Minutes |

HONEYCOMB CORE A2 -ACP | 55 Seconds |

Different Types of Cores

PERFORMANCE | LDPE | OVER 70% Mineral EN 13501 B | OVER 90% MINERAL EN 13501 A2 | OVER 90% METAL | 100% METAL |

Combustibility Rating | Combustible | Low Combustibility | Non | Non-Combustible | Non-Combustible |

NFPA 285/ BS 8414 Pass | No | Yes | Yes | Yes | Yes |

ASTM E 84 Core | No | Yes | Yes | Yes | Yes |

ASTM D 1929 Ignition | No | Yes | Yes | Yes | Yes |

EN 13501 S1 D0 Rating | E | B | A2 | A2 | A1 |

Direct Flame Over | 20 Seconds | 18 Minutes | 30+ Minutes | 55 Seconds | 30 Seconds |

ALUMINIUM PANEL FIRE TEST:

A panel burning test was conducted with the direct flame at a temperature of 1500 0C on five different panels. The time the panels withstood fire was recorded as follows.

Panels | Time withstood by Panel |

LDPE Core – ACP | 20 Seconds |

Solid Aluminium | 30 Seconds |

B1 Core -ACP | 18 Minutes |

A2 Core -ACP | 30 Minutes |

HONEYCOMB CORE A2 -ACP | 55 Seconds |

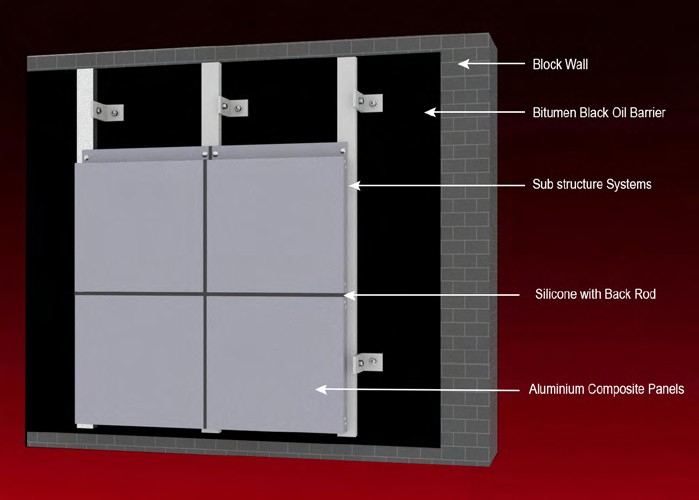

NFPA 285:2012 FR Standard Test Alubond (FR-A2, FR-B1) with ABTI Substructure System

Alubond–Stone (Alubond A2 & Alubond B1) undergoing the NFPA 285 Test in two International Third Party Laboratories Intek USA and Thomas Bell-Wright International Consultants, U.A.E

Fire Test for Russian Gost R Certificate

ASTM E84-15: Standard Test Method for Surface Burning Characteristics of Alubond(FR-A2, FR-B1)

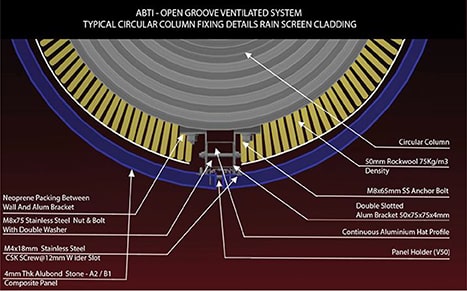

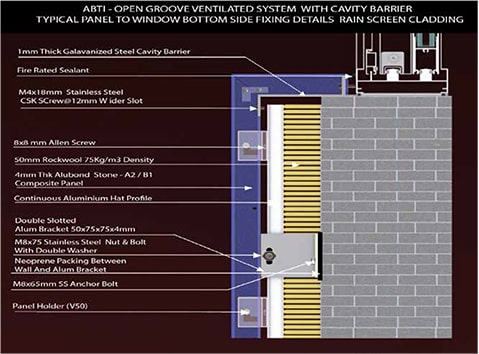

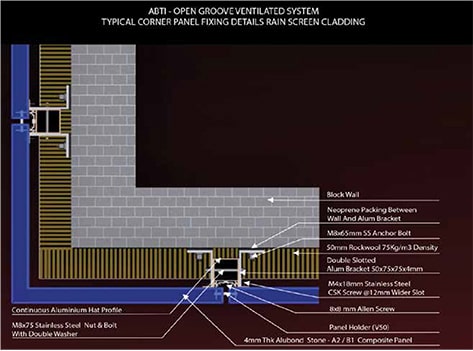

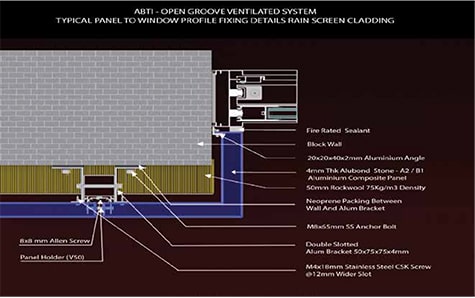

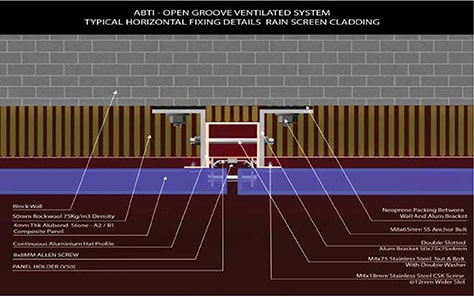

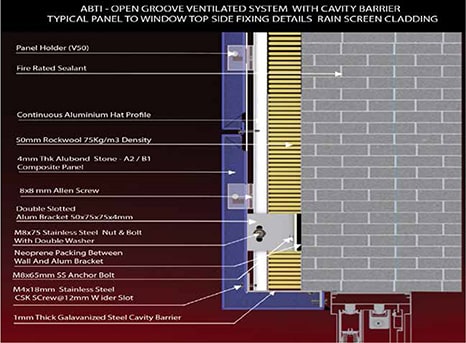

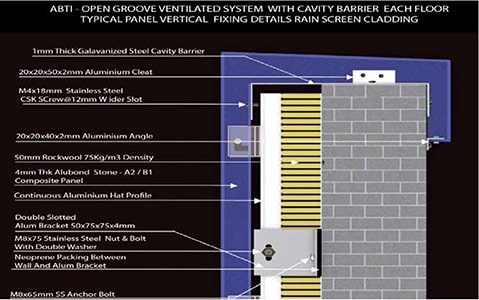

ABTI-Open Groove Ventilated Substructure System

Typical Corner Panel Fixing Details Rain Screen Cladding

Typical Panel Window Bottom Fixing Details

Typical Panel Window Top Fixing Details

Typical Horizontal Fixing Details

Typical Panel to window Fixing Details

Typical Roof Top Fixing Details

Typical Panel Column Fixing Detail

EN 13501-1:2007+A1: 2009

ENVIRONMENTAL PRODUCT DECLARATION ALUBOND–STONE (FR-A2)

EN 13501 – TEST

RUSSIAN GOST R CERTIFICATE